In healthcare, innovation depends on parts most people never see. From surgical tools to diagnostic sensors, progress is built on specialised components sourced from around the world. When those parts are delayed, the entire product stalls. When they run short, patient care is put at risk.

The latest Custom Parts and Components Sourcing Survey, presented at Haizol, the leading marketplace for custom manufacturing online, Supplier Discovery and Sourcing Breakthrough Conference in Shanghai, reveals how procurement itself is being reshaped. The findings point to a new reality: speed, precision, and supplier visibility now matter more than scale.

A Sector in Transition

The survey drew responses from more than 220 procurement leaders and over 1,000 manufacturers across 60 sub-sectors. Three themes stood out:

- Procurement cycles are accelerating.

- Bulk contracts are giving way to smaller, specialised runs.

- Demand is surging in innovation-led industries, with medical technology high on the list.

For healthcare, these shifts create opportunity and exposure at once. Faster access to custom parts can speed trials and reduce costs. But short payment cycles can amplify risk.

The Rise of Short Runs

Medical devices rarely go straight to mass production. They move through rounds of prototypes and pilot batches before reaching patients. Until recently, finding suppliers willing to take on small, fast-turnaround runs often came at a premium, or wasn’t possible at all.

That barrier is fading. More medical device molding companies are now open to low-volume contracts, making it easier for medtech companies to test, iterate, and bring products to market without tying up capital in large orders. In practice, this could mean a diagnostic device reaches trial six months sooner, or a surgical tool is refined in weeks instead of years.

Medtech Moves Up the Agenda

Healthcare is no longer peripheral to global supply chains. It is helping to shape them. In the survey, robotics, semiconductors, and medical technology together accounted for more than half of sourcing demand. Robotics alone represented 11%, much of it linked to surgical systems and rehabilitation devices.

Factories once focused on telecoms or automotive contracts are now retooling for medical-grade precision. Casings for wearables, housings for imaging systems, and implantable components are appearing on production floors that once turned out consumer electronics. For healthcare organisations, this widening pool of capable suppliers is both an opportunity and a challenge: access has improved, but competition for capacity is intensifying.

When Finance Meets Procurement

Cash flow is now a front-line variable. The survey shows:

- 43% of contracts close on 30-day terms.

- 31% demand pre-payment or cash.

- Only 6% extend to the 90-day cycles many procurement teams once relied on.

For medtech startups, faster settlement can secure supplier commitment and speed delivery. But it also compresses already tight financial margins. But companies alike must now treat payment terms as strategic levers, not administrative details.

Why It Matters

The data points to a simple truth: procurement has moved beyond scale. What matters now is speed, transparency, and fit. For healthcare, this means:

- Earlier access to innovation through smaller runs.

- A broader pool of suppliers equipped for medical standards.

- New financial pressures that tie sourcing decisions to cash strategy.

- Greater risk if supplier verification is overlooked.

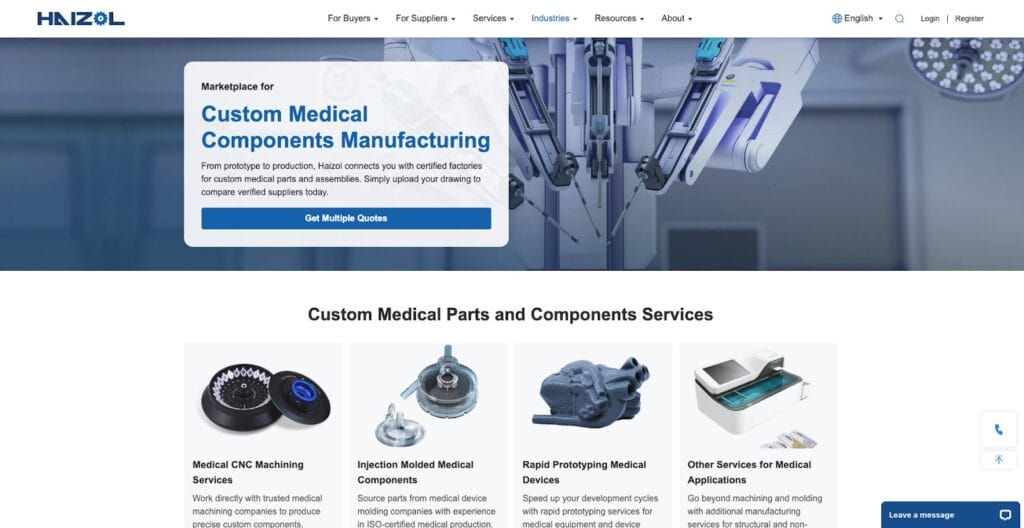

Closing this gap is where online platforms for medical device manufacturing, such as Haizol, come into play. By mapping supplier capabilities against technical requirements and highlighting certified medical machining companies, Haizol offers healthcare organisations a way to cut through opacity and reach trusted partners.

The factories are out there. The capabilities are proven. What’s been missing is a smarter way to surface them. And that is the role Haizol is beginning to play in reshaping how custom medical components move from factory floor to patient care.

The Editorial Team at Healthcare Business Today is made up of experienced healthcare writers and editors, led by managing editor Daniel Casciato, who has over 25 years of experience in healthcare journalism. Since 1998, our team has delivered trusted, high-quality health and wellness content across numerous platforms.

Disclaimer: The content on this site is for general informational purposes only and is not intended as medical, legal, or financial advice. No content published here should be construed as a substitute for professional advice, diagnosis, or treatment. Always consult with a qualified healthcare or legal professional regarding your specific needs.

See our full disclaimer for more details.